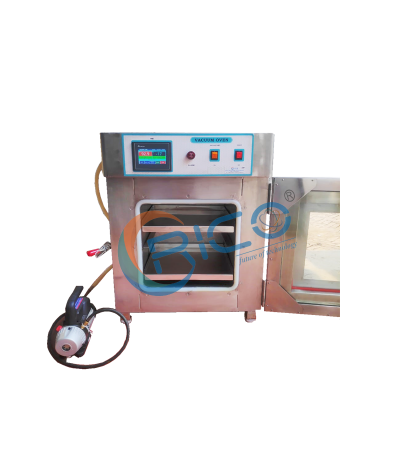

Vacuum oven heating devices from RICO are designed to operate under normal atmospheric pressure or vacuum conditions of up to 30"Hg, in a wide temperature range, for day-to-day heating and vacuum drying applications. Designed for precise temperature control and equipped with a flexible vacuum system, they use cosmetics, books, foods, watches Provide fast and soft drying solutions for PCB and other electronic components such as heat-sensitive and air-sensitive materials. These vacuum heating and drying ovens are designed for excellent temperature and vacuum performance, which are used for the drying of samples and Provide their facility for dissolution, powder drying, vacuum embedding and electronic component processing. Rapid and highly efficient find vacuum oven employed for a wide range of scientific and research applications and research laboratories, widely used in defense establishments, educational institutions and industrial units.

Vacuum ovens are available in different sizes and configurations from RICO and are fully customizable according to specific requirements. They are designed according to ASTM standards and bear CE certification for safety and reliability. Vacuum ovens are essentially double walled devices, which are made of powder coated galvanized sheet with high quality, heavy gauge SS-304 stainless steel interior surfaces and paint finishes to the outer surfaces. The equipment has highly resistant and non-corrosive outer and internal surfaces and the internal surfaces are welded for easy weld and strong bracing. The gap between the outer and the internal wall is full of high grade mineral glass wool for maximum thermal efficiency. The double plume design of these vacuum oven ensures an external outer surface for easy handling of the equipment. Equipment is also provided with a strict glass door for enlarged visibility.